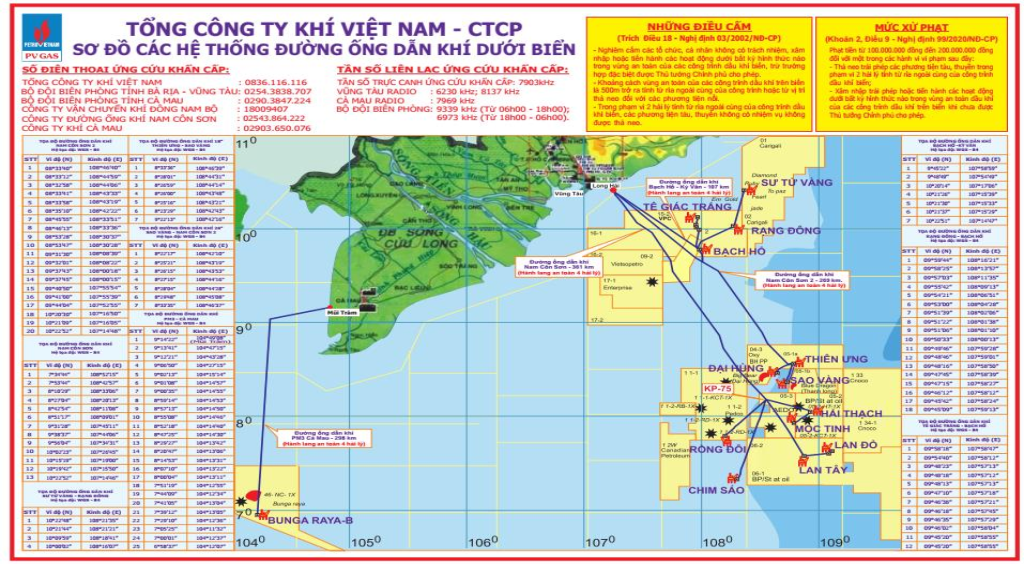

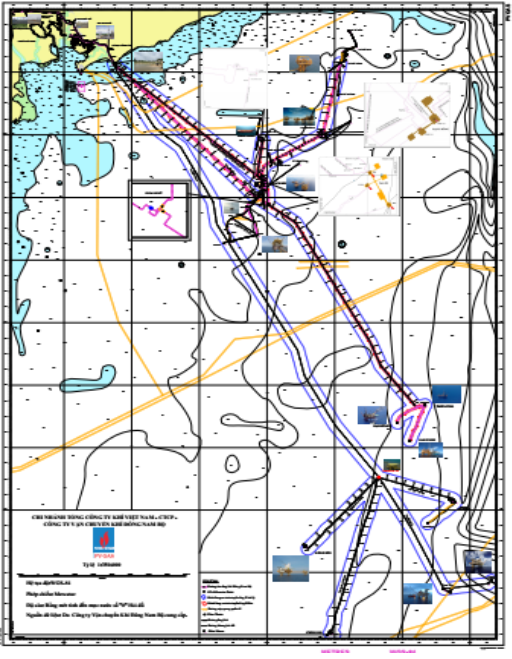

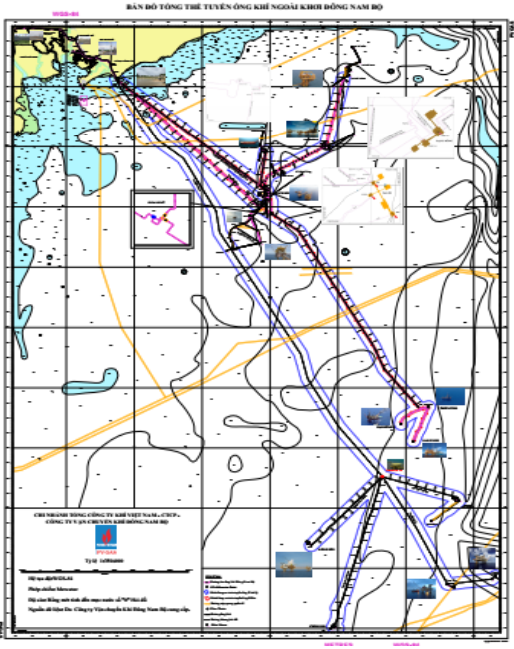

GAS PIPELINE INFORMATION

Bach Ho – Ky Van Gas Pipeline

The Bach Ho – Long Hai – Dinh Co gas pipeline has been in operation since 1997. It starts from the Bach Ho Central Platform and extends to the Long Hai Onshore Terminal, ending at the Dinh Co Gas Processing Plant (DC GPP). Its purpose is to transport all gas sources from the central compression platform of Bach Ho.

This pipeline is buried and has several above-ground structures that are exposed to external risks:

- The Subsea Safety Valve (SSVS) cluster is located 70m away from the Bach Ho Riser Block.

- Flange face connection between the spool and the pipeline at KP0.000, which is 80m away from the Bach Ho Riser Block.

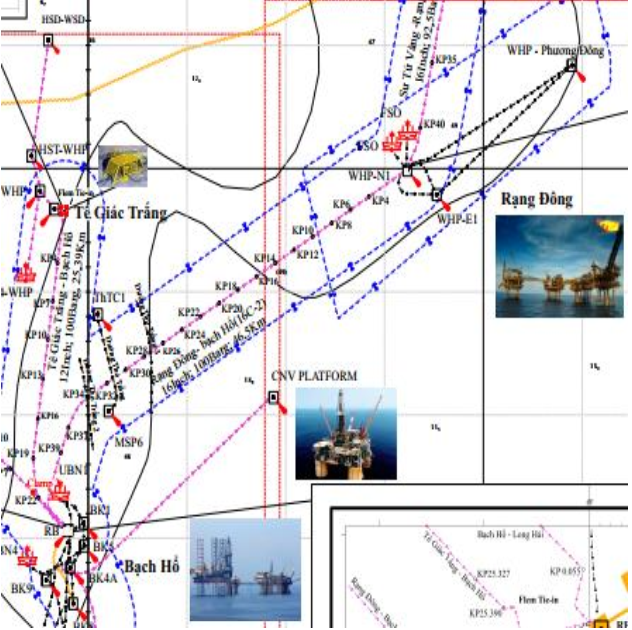

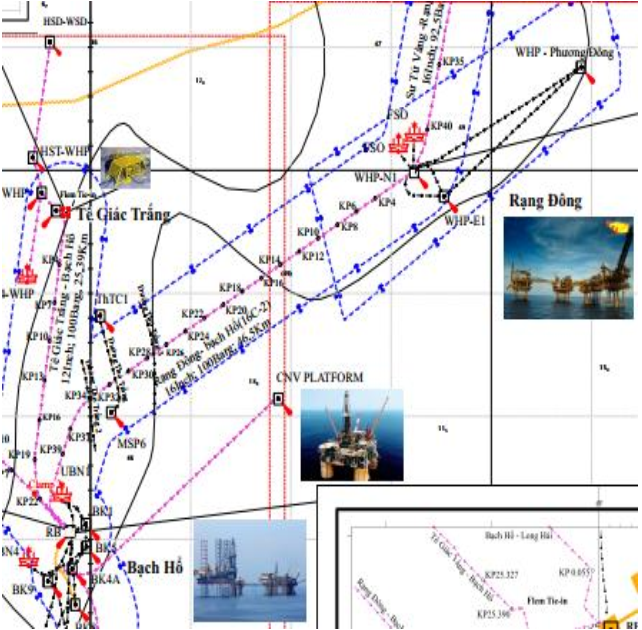

TE GIAC TRANG (TGT) – BACH HO GAS PIPELINE

The TGT – Bach Ho gas pipeline, operational since 2011, starts from the Gas Offtake Point (Floating Production Storage and Offloading – FPSO White Rhinoceros) and goes to the central gas compression platform of Bach Ho. This pipeline is floating and has several above-ground structures that are exposed to external risks:

- The Subsea Safety Isolation Valve (SSIV) cluster is located approximately 1km away from the Armada TGT vessel.

- The Pipeline End Manifold (PLEM) cluster is located approximately 1.2km away from the Armada TGT vessel.

- Barrad Tee at KP6.786.

- PLEM cluster is located approximately 300m away from the Bach Ho Riser Block.

- Flange face connections within a 500m radius around the Bach Ho Riser Block.

SU TU VANG (STV) – RANG DONG GAS PIPELINE

The 16″ STV – Rang Dong gas pipeline, operational since 2009, starts from the Golden Lion Platform and ends at the Rang Dong Wellhead, used to collect associated gas from the Cuu Long Basin. This pipeline is floating and has several above-ground structures that are exposed to external risks:

- The Subsea Safety Isolation Valve (SSIV) cluster is located approximately 40m away from the Golden Lion platform.

- Barred Tee at KP1.196 and KP24.238.

- Rang Dong PLEM cluster is located approximately 100m away from the Rang Dong platform.

- Flange face connections within a 500m radius around the platform.

RANG DONG – BACH HO GAS PIPELINE

The 16″ Rang Dong – Bach Ho gas pipeline, operational since 2001, starts from the WHP-N1 platform at Rang Dong and goes to the Bach Ho platform. It is used to transport associated gas collected from various fields to the Bach Ho platform. This pipeline is floating and has several above-ground structures that are exposed to external risks:

- The Subsea Safety Isolation Valve (SSIV) cluster is located approximately 150m away from the Bach Ho Riser Block.

- Flange face connections within a 500m radius around the Bach Ho Riser Block.

NAM CON SON 2 GAS PIPELINE

The gas from Thien Ung – Dai Hung will be transported to the Sao Vang CPP (Central Processing Platform) and compressed. It will then be transported along with the Sao Vang Dai Nguyet gas to the NCS2-GD2 pipeline. The pipeline system includes:

- 23km of 18″ pipeline from the PLEM at BK-TNG to SV-CPP.

- 22km of 26″ pipeline from the PLEM at BK-TNG to SSCV at SV-CPP.

- 117km of 26″ pipeline from KP207.5 to Long Hai.

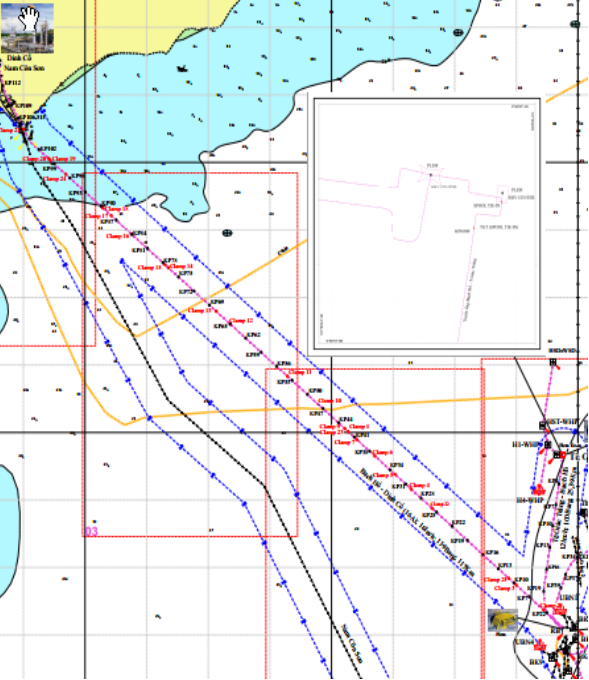

NAM CON SON 1 GAS PIPELINE

The Nam Con Son offshore gas pipeline transports gas from the Lan Tay, Rong Doi, Chim Sao, and Hai Thach – Moc Tinh fields to the onshore reception point at Ky Van, Long Hai.

- The 26″ pipeline spans approximately 362 km from Lan Tay – Ky Van, Long Hai.

- The entire NCSP offshore gas pipeline is buried beneath the seabed, except for the KP75 location (connection area of the fields), which has underwater structures resting on the seabed.

KEY HAZARDS FACED BY OFFSHORE GAS PIPELINES

- Pipeline Vulnerabilities: Potential Intrusions: One of the primary hazards facing offshore gas pipelines is the risk of intrusions. This can occur due to various activities, such as exploration, surveys, and maintenance operations conducted in the vicinity of the pipelines. Additionally, the presence of service vessels, cargo ships, law enforcement boats, and fishing vessels in the area further adds to the concern. These intrusions can potentially lead to accidental damage or disruption to the pipelines, causing safety and operational risks.

- Collisions and External Hazards: Collisions and external impacts pose significant threats to the integrity of offshore gas pipelines. During exploration, surveys, and maintenance activities, there is a risk of vessels or platforms inadvertently colliding with the pipelines. The drifting of vessels and platforms in rough weather conditions can also lead to collisions, jeopardizing the stability of the pipelines. Moreover, fishing gear and fishing operations in the vicinity of the pipelines create additional hazards, as well as the potential risks associated with the construction of structures near the pipelines.

- Explosive Material Hazards: The presence of explosive materials in the vicinity of offshore gas pipelines presents a severe safety concern. This hazard may arise from military exercises being conducted in the area, with the risk of unintended explosions affecting the pipelines. Furthermore, there have been instances of fishing activities employing explosive materials, which not only endanger marine life but also pose a significant threat to the pipelines’ integrity. Additionally, concerns of intentional sabotage or deliberate damage with explosive materials are also critical factors that need to be addressed to ensure the safety and security of offshore gas pipelines.

PREVENTION METHODS

- INSTALLATION MONITORING: Implement continuous monitoring systems during pipeline installation and operation to detect any potential intrusions or damages in real-time.

- MARINE TRAFFIC MANAGEMENT: Establish strict marine traffic management protocols around pipeline areas to minimize the risk of collisions and impacts with vessels and platforms.

- SAFETY ZONES: Create safety exclusion zones around pipeline installations to limit access and reduce the chances of accidental intrusions. It is stated in Vietnam Regulations that 2 NM from the end of any offshore structures (including underwater gas pipelines) is forbidden to drop anchor unless the vessel has a specific responsibility in the area (such as maintenance, emergency response)

- DIVER AND REMOTELY OPERATED VEHICLE (ROV) INSPECTIONS: Regularly inspect the pipelines using divers or ROVs to identify any damages or vulnerabilities and perform necessary repairs promptly.

- ANCHORING RESTRICTIONS: Enforce restrictions on anchoring in pipeline areas to avoid unintentional damage caused by anchor impacts.

- UNDERWATER SURVEILLANCE: Deploy underwater surveillance technologies like sonar or video monitoring to monitor pipeline conditions and detect any unauthorized activities.

- WARNING BUOYS: Install warning buoys or markers around the pipeline area to alert vessels and fishing boats about the presence of the pipeline and to maintain a safe distance.

- TRAINING AND AWARENESS: Provide comprehensive training to vessel operators, fishing crews, and personnel involved in pipeline operations to raise awareness about potential hazards and safe practices.

- EXPLOSIVE MATERIAL CONTROL: Enforce strict regulations to prevent the use of explosive materials for fishing or any other purposes near pipeline installations.

- SECURITY MEASURES: Implement security measures, including surveillance cameras, fencing, and patrols, to deter and prevent acts of sabotage or deliberate damage to the pipelines.

- RISK ASSESSMENTS: Conduct regular risk assessments to identify new potential hazards and develop proactive measures to address them.

- EMERGENCY RESPONSE PLAN: Have a well-defined emergency response plan in place to address any incidents promptly and minimize the impact on the pipelines and the environment.

By adopting these prevention methods, offshore gas pipeline operators can significantly reduce the risk of accidents, maintain the integrity of the pipelines, and ensure the safety and sustainability of their operations.

Source: PV GAS – Conference on Communications for the Security and Safety of Underwater Gas Pipelines.